Plate Heat Exchangers

Product Information

World Heat offer both Gasketed and Brazed Plate Heat Exchangers. Plate Heat Exchangers (PHEs) provide a highly efficient method of heat transfer between two separate mediums and have several advantages over the traditional shell and tube heat exchangers available. They are typically much smaller in comparison, can be easily modified by adding or removing plates to increase/decrease duty (gasketed version only), can be easily maintained and are typically more resistant scaling and fouling due to the high flow rates within the unit.

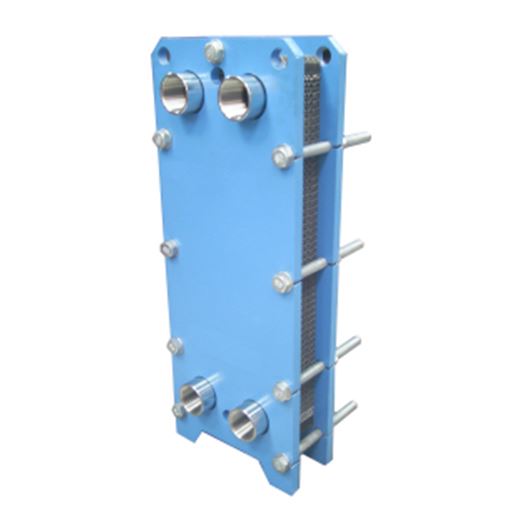

Gasketed Plate Heat Exchangers

Gasketed Plate Heat Exchangers consist of three main components. A number of pressed, corrugated stainless steel plates are arranged to give a honeycomb pattern. Each plate sealed by a gasket to form the plate pack. The plate pack is then sandwiched between two carbon steel pressure plates which are subsequently bolted together. Depending on the size of the unit, a carrier bar may also be provided to aid maintenance and plate replacement.

Brazed Plate Heat Exchangers

Brazed Plate Heat Exchangers consist of a metallic plate pack sandwiched between a front and rear coverplates. Gaskets are not included, instead the plates are brazed together with pure copper. Brazed Plate Heat Exchangers are extremely compact and typically able to withstand higher pressures than standard Gasketed units.

Accessories Available

- Insulation – With each of our Gasketed/Brazed Plate Heat Exchanegrs we offer a bespoke fit insulation jacket. The jacket is fitted with a Velcro Fastening system which allows for easy removal and re-fitting.

- Splash Guard – Stainless Steel guards are offered for use in applications where personnel may be at risk from coming into contact with the hot and sharp surface of the plate pack.

- Drip Tray – Stainless Steel drip trays can be provided to collect the medium from a Gasketed Plate Heat Exchanger during dismantling and draining.

Packages

World Heat are able to offer a range of bespoke Plate Heat Exchanger Packages for a range of applications including; DHW, LTHW, MTHW and Steam. A multitude of configurations are available to suit the client’s specific requirements which can include package mounted;

- Storage Vessels

- Controls

- Unvented Kit

- Pump Sets

Please contact our technical sales team if you have any queries or enquiries please feel free to call on 0161 343 8610 or email sales@whcylinders.co.uk