Low Loss Headers: Optimising Hydraulic System Performance

World Heat Cylinders designs and manufactures high-efficiency Low Loss Headers, also known as hydraulic separators. These crucial components are engineered to ensure that boilers, heat pumps, and other heat sources operate at their optimum efficiency. This is achieved by maintaining the water flow and velocity through the heat exchanger within specified design conditions, effectively decoupling the primary heat source circuit from the secondary heating circuits.

Fitting a low loss header in your hydraulic circuit allows the required flow and velocity to be constantly maintained within the primary circuit. This, in turn, maintains the maximum efficiency of the heat source, irrespective of varying flow rates or demands in the secondary circuits.

Why Use a Low Loss Header?

Integrating a low loss header into your heating system offers several key advantages, particularly in complex or multi-zone installations:

- Hydraulic Separation: It effectively separates the primary circuit (heat source) from secondary circuits (e.g., radiators, underfloor heating zones). This means pumps in one circuit do not interfere with pumps in another.

- Maintained Flow Rates: Ensures the heat source (boiler or heat pump) always receives its designed minimum flow rate, preventing issues like short cycling, overheating, or reduced efficiency.

- Pump Protection: By providing a point of common pressure, low loss headers can help protect pumps from operating against closed valves or dead-end conditions.

- Improved System Control: Allows for more stable and responsive control of individual heating zones without adversely affecting the heat source operation.

- Air and Dirt Separation (with appropriate fittings): Many low loss headers are designed to facilitate the removal of air and dirt from the system when equipped with automatic air vents and drain cocks, further enhancing system efficiency and longevity.

- Suitability for Low Water Content Systems: Modern boilers and heat pumps often have low water content. A low loss header, sometimes in conjunction with a buffer vessel, helps provide the necessary system volume and stability.

WH Cylinders Low Loss Header Range & Features

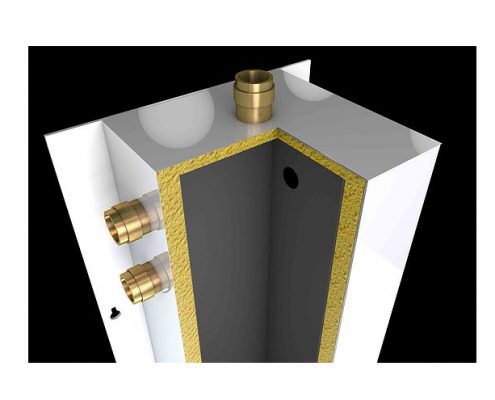

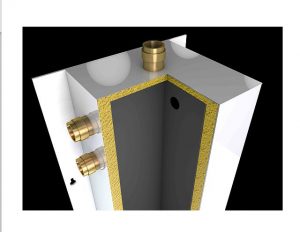

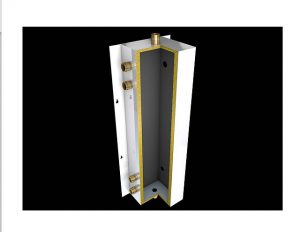

WH Cylinders offers a standard range of pre-insulated and highly efficient Low Loss Headers. We manufacture these in high-grade mild steel or stainless steel, tailored to the specific dimensions and capacity of your heating system. Consequently, our headers can be either wall-mounted or floor-mounted, depending on size and site requirements.

Standard features often include:

- Factory-fitted automatic air vent to remove entrained air.

- Drain valve for system flushing and maintenance.

- Various types of high-performance insulation and durable casing options to minimise heat loss.

- Multiple sensor pockets for system monitoring.

Furthermore, we manufacture low loss headers in many different shapes and sizes to suit your exact requirements. If your project has specific needs outside of our standard product range, such as unique connection sizes, orientations, or flow rate demands, please do not hesitate to contact our technical design engineers. Indeed, they will be able to assist in your enquiry and design a bespoke low loss header solution.

Product Information Sheet

For detailed technical specifications of our standard Low Loss Header range:

Discuss Your Low Loss Header Requirements

To ensure optimal performance and efficiency for your heating system, selecting the correct low loss header is vital. For expert advice, assistance with sizing, or to discuss a bespoke design, please contact our experienced technical sales support team.

Therefore, call us today on 0161 343 8610, email sales@whcylinders.co.uk, or get in touch via our contact form.